Connections

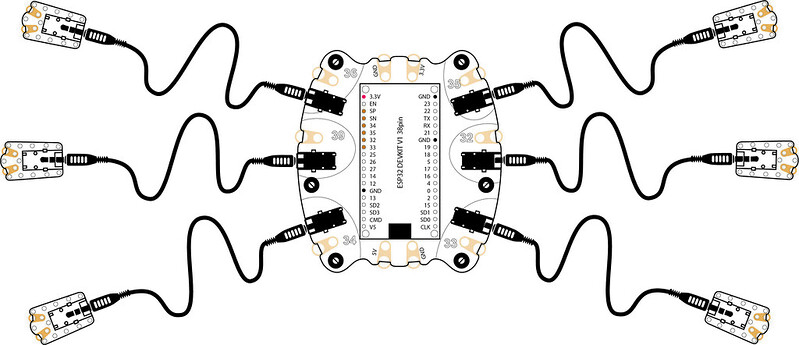

Spaghettimonster

the spaghetti monster is basically the idea to use 3.5mm audio sockets and cables to make 2/3/4-way connections between the gpio pins of a microcontroller board and textile/wearable sensors & actuators mounted around the body. specifically a first instance of this idea was designed to breakout 6 analog pins of an ESP32 Devboard to connect […]

Super Stretchy & Robust Conductor

This is NOT a stretch sensor, but rather the opposite, a way of making a stretchy connection/lead/trace. A tube knit from conductive thread with round elastic inserted. Before finishing the ends, the knit tube is stretched to it’s max and elastic’s max stretch (or other max can be taken) and then fixed. You can work […]

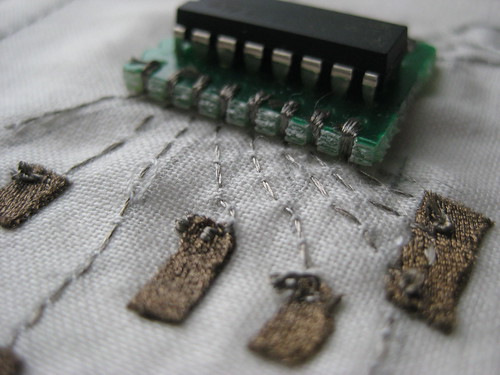

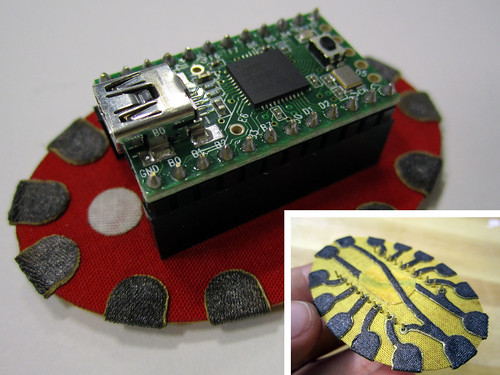

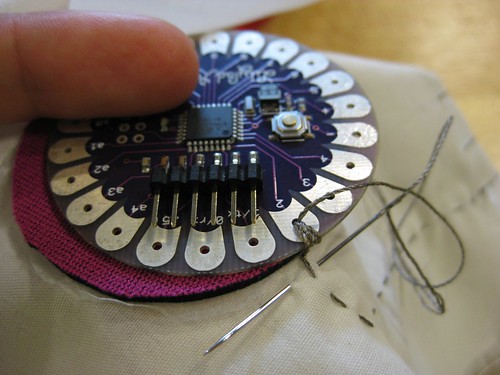

Felted DIP socket

When using microcontroller for embroidery circuit projects, sometimes you do not want to directly solder them on the embroidery as you need to take it out to change the program on it. For this, sockets are convenient, but it is also bulky on the fabric. I used 5mm felt, that is as thick as the […]

Lulu as 4-Way Adapter

Instead of soldering the LED to the tip of the Lulu BEE you could solder the ends of 4-wires to the pads on the PCB. Thus the Lulu becomes a 4-way e-textile to wire adapter… connector… breakout…

Pivoting 3-Way Connection

A snap connection not only makes for a robust e-textile electrical connector, it also make for a great pivot point. When you have a single electrical connection to make the snap can double as both electrical connection and pivot point. But what when you have more than one electrical connection?

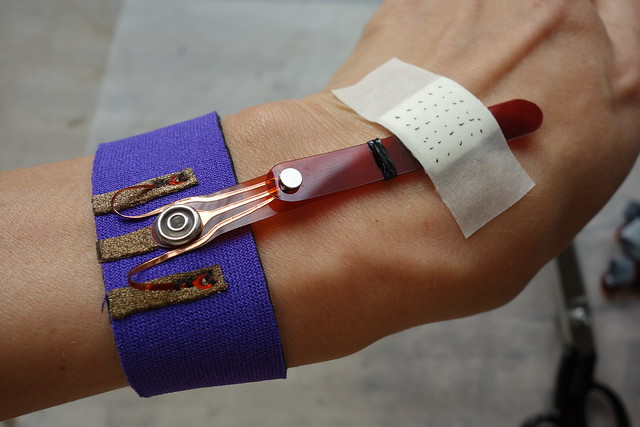

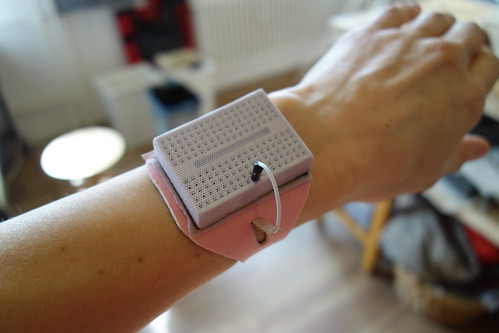

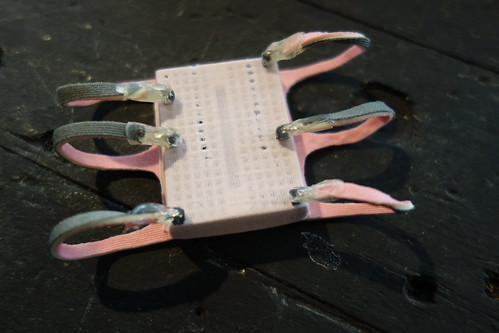

Body to Breadboard Bracelet

Inspired by this upcoming workshop during E-Textile Spring Break titled “Body to Body: RFID + PAN Workshop, where Ingo + Nicole will “…introduce a DIY implementation of these systems to pass data through bodies to other bodies”. To make the connection between the body and the breadboard, this bracelet has conductive fabric on the back/bottom […]

Elastic Waistband with Motor Pouches

In order to create our own version of a “Northbelt” built into the elastic of a jumpsuit waistband, we developed a technique for laying out the circuit’s traces along the length of the elastic, and then jumping inside to tight-fitting pouches that fit vibration motors mounted on 2x5cm boards. The traces from the circuit run […]

fabric button circuit

When making eTextile circuit, the solder joint between hard component and conductive textile material tend to break as it get the most strain from flexing. To avoid this, the whole circuit can be placed on a fabric button so that it does not get bent. Here is the test LED embroidery circuit on a fabric […]

Making Connections

As part of thinking about robustness and durability in our e-textile tailor shop, I’m revisiting some of the ways we’ve been making permanent and detachable connections between hard and soft components of e-textile circuits.

Beaded Multi-wire

Using beads to insulate multiple conductive threads next to one another coming from an e-textile circuit, ending in male header pins.

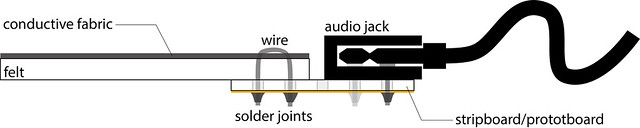

Wire to Conductive Fabric Connection

in progress… Inspired by Vaclav’s Magic Shoe connections… Poke wires through strips of conductive fabric and soldered them to stripy protoboard. Solder quickly at low heat to avoid that the heat of the soldering will melt the stretch conductive fabric and burn the conductive layer of silver.

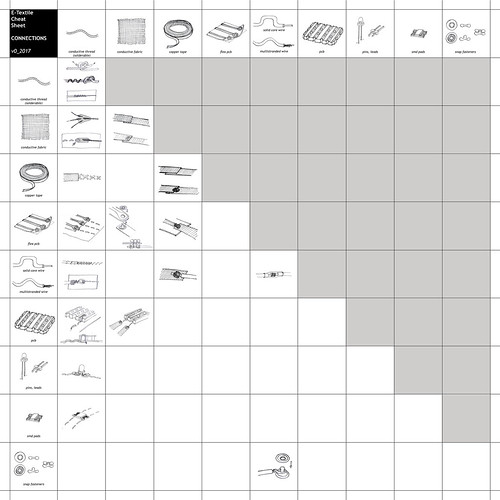

E-Textile Cheat Sheet

— work in progress — Making electrical connections and not making electrical connections are the most common challenges when working with electronic textiles. This chart lists a variety of materials and ways of making connections (making contact) and not making connections (insulating) between them.

Common GND

Breadboard to Metal Snap Converter The worlds of electronics and textiles are separated by their inability to connect across shared connections. But in the world of electronic textiles you want to be able to share power, data, GND. To bridge this gap, and make electrical connections between these separated worlds, I made this breadboard to […]

Hard to Soft Snap Connection

An example of how to make a metal snap connection between a hard (circuit board, speaker, component…) and a soft (fabric, thread….) element.

Chaining Components

This design was made as part of the Stulpe Circuit Project To keep the circuit flexible, parts and functionality are groups into small areas with flexible areas in between. one option is to make the hard nodes from hard PCB material and solder wire connections in between (see photos). Another option would be to design […]

Hard/Soft Connections

There are a range of different possibilities to connect conductive materials. One of the hardest and at this point very relevant one in textile electronics is the hard/soft connection between conductive textiles and traditional components and circuit boards. Most connections are a combination of permanent and plugable (de- and re- attachable) connections. Here we try […]

Electroplating Conductive Farbrics

Conductive fabrics and threads can be plated without having to first coat them in conductive paint because they are already conductive! It can be a great way to make a conductive fabric solderable to then make a robust solder connection to a soft fabric circuit. Here are some examples of different conductive fabrics and threads […]

Lasercut Fabric Breakout

This conductive fabric breakout circuit is also an example of a plugable hard to soft connection.

Improved Electrical Contact

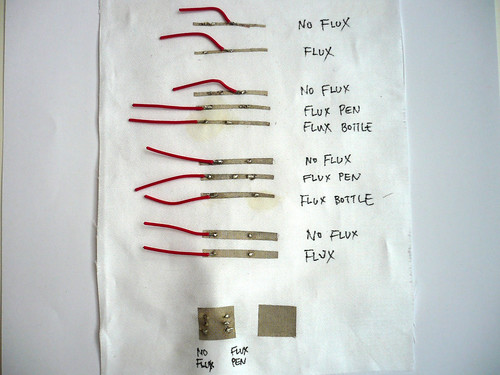

Tips on how to improve your electrical contacts between various materials. It is always good practice to test a certain connecting technique before applying it to more than one connection.

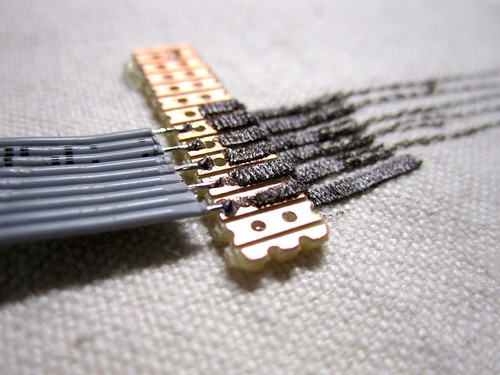

Soldering Conductive Thread

also see: Materials >> Conductive Threads You can’t solder to most conductive threads, but there are conductive threads that are actually made by spinning very thin flattened wire around a soft, flexible core, and these are great for soldering to.

Soldering Conductive Fabric

also see: Materials >> Conductive Fabrics Of the conductive fabrics I tried soldering to, only the copper FlecTron fabric distributed by LessEMF was very reliable. There was another silver fabric that worked, but I don’t know the source. The Laird conductive fabric tape was also good, so were copper mesh and copper foil tape with […]

Flux Test

I had hard time soldering DIP pin legs to conductive fabric. It becomes always crumbly and does not stick to the fabric good. (Also I am using lead free solder, that makes it look crumbly too)